From the June 1965 issue of American Rifleman, an article about cleaning the bore of a smallbore rifle and how it can affect accuracy. By L.F. Moore.

Cleaning the bore

The frequency of cleaning the bore of the smallbore rifle varies widely among shooters, and match-winning scores are produced by individuals whose cleaning practices differ greatly.

Until 1937 several brands of smallbore match ammunition were loaded with a Lesmok propellant. This propellant, abandoned in 1947, was a mixture of black powder and guncotton which left a rust-producing salt residue in the bore on firing. Also, under some conditions it left fouling. It was necessary to clean the bore at least after each day of firing to avoid rustling or fouling. It is understandable that shooters developed the habit of frequent cleaning.

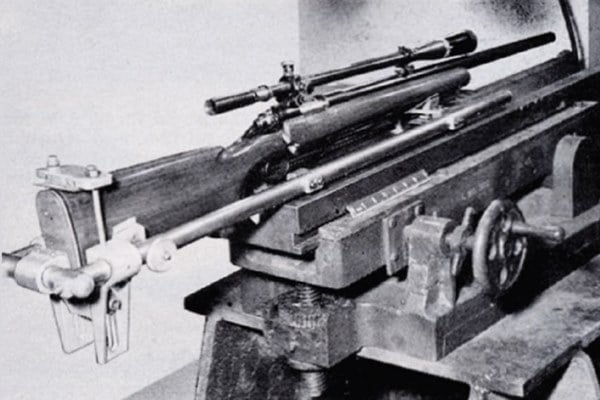

Recently, an extensive test was carried out to determine whether, under normal conditions, cleaning the bore of the smallbore match rifle is necessary. Four rifles were used to fire a total of 3800 rounds. Two M40X Remington rifles in new condition were selected to represent average match rifles, and one M37 Remington with an Eric Johnson barrel and a custom stock was selected to represent a rifle with a rough bore. Over 50,000 rounds had been fired in the Johnson barrel; the bore was very rough at 6 o’clock for about 2″ at the breech end, and there was some roughness at 6 o’clock throughout the rest of the bore. An additional rifle, an M52C Winchester in new condition, was used as a control. All firing was conducted under conditions as nearly uniform as possible except for bore condition and barrel temperature. The firing was done from a machine rest on a 100-yard enclosed range. A 20x telescope sight was mounted on the rifle.

A preliminary test was conducted for the purpose of selecting a lot of ammunition for each rifle which would give representative smallbore rifle accuracy. One lot of ammunition was fired in the M37, seven lots were fired in each M40X, and four lots in the M52C.

Testing at 2 temperatures

Two tests were then carried out, one at ambient and one at high temperature. In each test, five 10-round groups were fired without sighting or fouling shots in each of the two M40X and the M37 rifles. One target was set up directly before a second and, since the machine rest was not moved during the firing of a particular rifle, it was possible to obtain five 10-shot and one 50-shot groups by changing the front target after each 10 rounds.

Immediately after firing the five 10-shot groups, the rifle bore was cleaned without removing the rifle from the rest. The cleaning rod was a Parker-Hale. First a bronze brush was passed through the bore six times (three cycles). The brush was removed and a tip was assembled to accommodate a cotton cleaning patch. One patch saturated with Hoppe’s No. 9 bore cleaner was passed through the bore twice (one cycle). Two dry patches were then passed through the bore twice each (one cycle each). Five additional 10-shot groups were then fired without fouling shots. This procedure was repeated on three additional days. The M52C rifle fired five 10-shot groups on each day and it was not cleaned during this test.

The first shot fired from a rifle which had not been fired for some time was generally out of the normal group and on several occasions the second shot was also out of the group.

Excluding the first group, there was no significant difference in the size of the groups before and after cleaning. There was a day-to-day variation, not connected with cleaning, in groups fired with the M37 and the M52C rifles.

The above procedure for the ambient-temperature test was then repeated with the rifle barrel heated by six 250-watt infrared industrial reflector lamps positioned about 12″ from the barrel. The rifle was exposed to the heat for one hour prior to firing. The temperature, determined with a pyrometer, varied between 135°F and 180°F at different points on the barrel and at different times during the firing.

The temperature was sufficiently high to affect the definition of the telescope sight, apparently by condensation of moisture on the lenses. As in the previous test the difference in the group size before and after cleaning was not significant. In general, heating the barrel had an adverse effect on accuracy.

After completing the high-temperature test, the lamps were turned off and the rifles were permitted to cool. Each rifle then fired five 10-shot groups. The accuracy obtained after the rifles cooled was the same as that obtained in the ambient-temperature test.

Some fouling in bore

While no effect of fouling on accuracy was observed in these tests, some fouling is deposited in the bore of the smallbore rifle. The quantity is normally too small to be observed without an instrument giving magnification. Light fouling throughout the bore and frequently a comparatively heavy deposit at the bullet seat can be observed with a borescope after the rifle has fired considerable rounds. Fouling builds up gradually and in minute quantities during firing, and is difficult to remove even with a bronze brush.

It is possible for a bore to have unusual characteristics which would cause comparatively heavy fouling, but this would be uncommon on a match rifle. I have seen heavy fouling from firing modern rimfire ammunition in only two bores. One of these, in a match pistol barrel, had a rough finish. The other, that of a match rifle barrel which had been disassembled form the rifle, had a visible accumulation of fouling at one point. The reason for this deposit was not determined. The heavy deposit of fouling in both bores was removed with a few passes of a bronze brush.

It may be desirable to inspect the bore of match rifles periodically with respect to number of rounds fired. This can be done after pushing a patch through the bore to remove the loose residue which results from firing a round.

Except when the rifle has been exposed to adverse weather, it appears advantageous to clean the bore of the .22 rimfire rifle only infrequently.

[box type=”shadow” align=”aligncenter” ]Article appeared: https://www.ssusa.org/articles/2018/6/21/how-bore-cleaning-affects-accuracy/[/box]

Add comment